Generic Drug Standards: What You Need to Know About Safety, Quality, and Trust

When you pick up a generic pill, you’re not just saving money—you’re relying on a system built on strict generic drug standards, the rules that ensure generic medications work just like their brand-name counterparts in the body. Also known as bioequivalence requirements, these standards are enforced by the FDA and similar agencies worldwide to make sure every generic drug delivers the same active ingredient, in the same strength, and at the same rate as the original. It’s not magic. It’s science. And it’s why millions of people safely use generics every day.

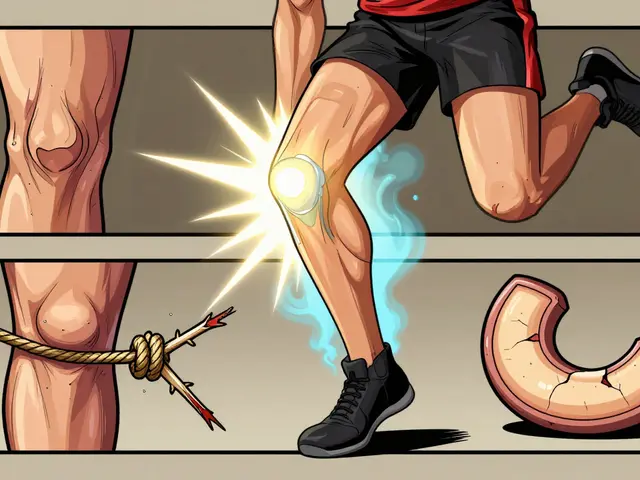

But here’s what most people don’t realize: bioequivalence, the process that proves a generic drug behaves the same way in your body as the brand version isn’t just about matching the chemical formula. It’s about how fast and how much of the drug enters your bloodstream. If a generic version releases the medicine too slowly or too quickly, it won’t work right. That’s why every single generic must pass real human studies—usually with healthy volunteers—measuring blood levels over time. The FDA requires the average absorption to fall within 80% to 125% of the brand drug’s levels. That’s not a guess. That’s a hard, measurable threshold. And it’s why a generic lisinopril for high blood pressure or a generic sertraline for depression works just as well as the name-brand version.

Then there’s drug quality, the set of manufacturing practices that ensure every batch of a generic drug is pure, stable, and free from contamination. This isn’t about the pill looking the same. It’s about the factory where it’s made. The FDA inspects over 3,500 generic drug plants globally each year—many more than brand-name facilities—because generics make up over 90% of prescriptions in the U.S. And if a plant fails inspection? The FDA halts shipments. No warnings. No second chances. That’s how serious they are. You might hear rumors about generics being made in "low-quality" countries, but the truth is, the same standards apply whether the pill is made in Indiana or India. The FDA doesn’t care where it’s made—they care if it meets the rules.

And what about side effects? If a generic has different fillers or coatings, won’t that cause problems? Sometimes, yes—but not because the active ingredient changed. Rarely, people react to inactive ingredients like dyes or lactose. That’s why your pharmacist will tell you if a generic switches manufacturers. It’s not about safety failure—it’s about individual sensitivity. The generic medication safety, the overall track record of generics being as safe as brand-name drugs over decades of use is strong. Studies from the National Academy of Medicine, the CDC, and the American Heart Association all confirm: no increase in hospitalizations or deaths linked to generics. In fact, because they’re cheaper, people take them more consistently—which actually improves outcomes.

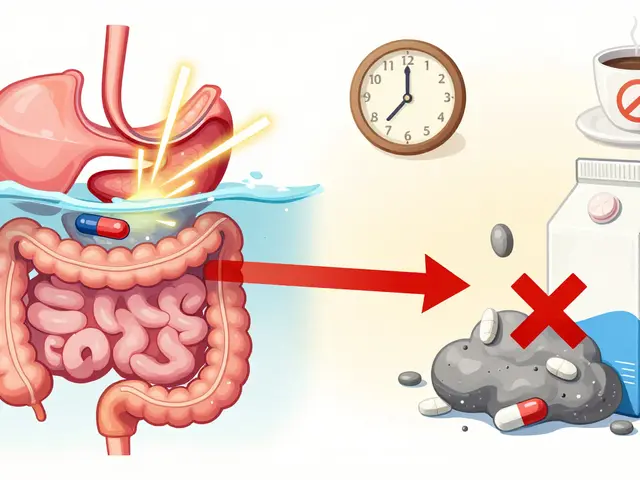

What you’ll find in the posts below are real, practical stories about how these standards play out in everyday life. From how calcium in your orange juice can block a generic antibiotic, to why your doctor might switch you to a different generic version of Effexor, to how FDA boxed warnings get updated after years of real-world use—these aren’t abstract rules. They’re the invisible guardrails keeping you safe. You don’t need to be a pharmacist to understand them. You just need to know what to look for—and what to ask.

Pharmaceutical Equivalence for Generics: What It Really Means When You Pick a Generic Drug

Pharmaceutical equivalence ensures generic drugs contain the same active ingredient, strength, and dosage form as brand-name versions. It's the first step to safe substitution-but not the only one. Learn what it really means for your prescriptions.

read more

FDA Safety Standards: How Generic Drugs Meet Brand Name Drug Requirements

The FDA ensures generic drugs meet the same safety and effectiveness standards as brand-name drugs through strict bioequivalence testing, manufacturing oversight, and labeling rules. Generics are not cheaper because they're weaker-they're cheaper because they don't repeat expensive clinical trials.

read more